Tagged with

Printed Electronics

Latest Posts

Silicon has emerged as the most widely used semiconductor material in the electronic industry, paving the way for the digital age. However, many are still oblivious to the unique properties and characteristics that make silicon ideal for a range of applications. This article explores the fundamentals of semiconductor materials, the properties of silicon that make it a prominent player in the semiconductor industry, and its diverse applications in electronic devices.

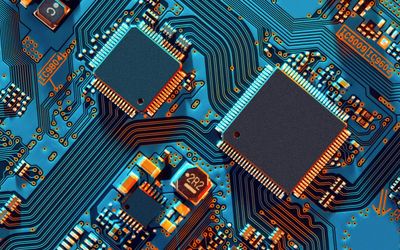

Castellation PCB is a type of printed circuit board (PCB) that has a series of small, plated through holes along the edges of the board. These holes are used to create a connection between the board and other components in a circuit. This article delves into the design, manufacturing, and testing processes involved in creating castellation PCBs, providing insights into the key considerations and guidelines that engineers and manufacturers should follow to optimize their designs for performance, reliability, and manufacturability.

Semiconductors are the building blocks of modern electronics, powering everything from smartphones to satellites. This in-depth guide provides a comprehensive understanding of semiconductors' engineering principles and applications, delving into their fundamental concepts, materials, devices, manufacturing processes, and their impact on today's technology landscape.

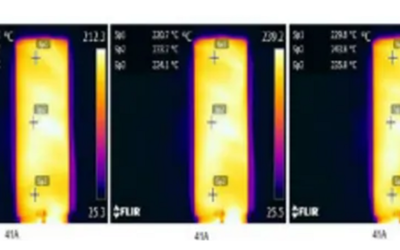

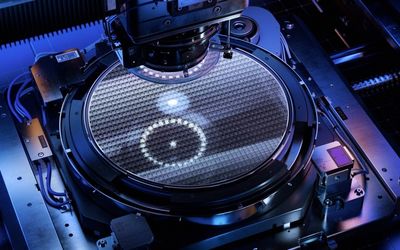

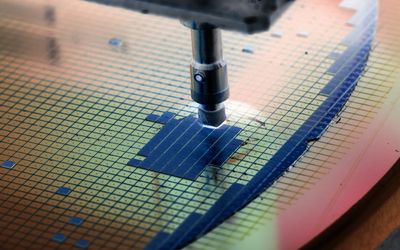

Wafer backgrinding is a crucial step in semiconductor manufacturing, as it prepares the wafer for further processing and packaging. The procedure comprises the thinning of silicon wafers by scraping out material from the backside, which is crucial for enhancing the functionality and dependability of semiconductor devices. This article examines the wafer backgrinding procedure, its difficulties, and the significance of quality control in ensuring the production of high-quality semiconductor devices.

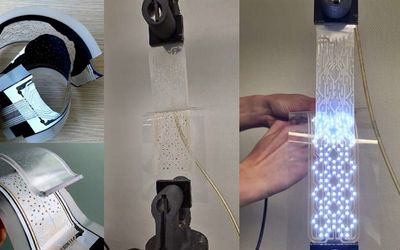

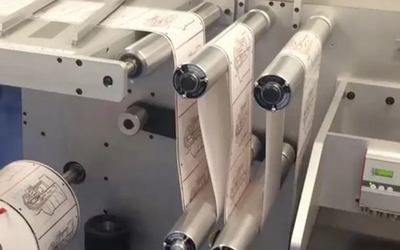

Healthcare is undergoing a transformative shift with the rise of stick-to-skin wearable monitoring devices. These data-collecting marvels, such as continuous glucose or cardiac monitoring devices, offer convenience & real-time insights.This article explores capabilities, applications & market trends