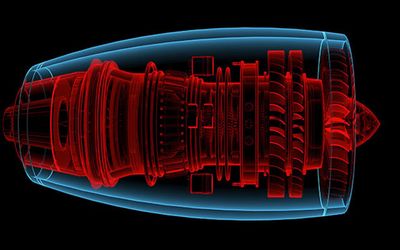

Over the last few decades, reverse engineering has become an essential part of product design and production processes used by manufacturers all over the globe. From aerospace to automotive to everyday consumer goods, industrial engineers and product designers rely on reverse engineering when replicating a legacy part without documentation or drawings, analyzing and deconstructing a competitive product, or modifying and improving an existing one.

Tagged with

manufacturing systems

Latest Posts

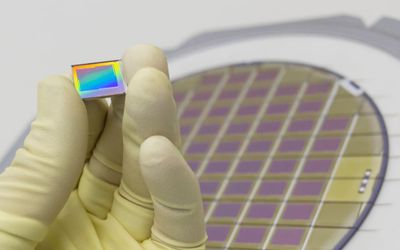

Wafer dicing separates individual integrated circuits or chips from a semiconductor wafer without damaging their delicate structures and circuits. This process is crucial for the production of electronic devices and components used in various industries, and the demand for it has increased with the development of high-performance and smaller electronic devices. Different dicing techniques, such as blade dicing, laser dicing, and plasma dicing, have been developed, and new innovations continue to emerge to address the challenges of complex semiconductor devices.

No one Olympics athlete can achieve gold medal without hard training. Just like a popular product needs "hard training" ---the repeated design, verification and improvement, before going to market. When it comes to this point, it is extremely crucial to find a qualified and suitable low-volume manufacturer along your product development.