Tagged with

manufacturing systems

Latest Posts

The injection molding cost is a common focus of plastic product manufacturers who use the process. It is an agglomeration of different factors and elements, and understanding such factors and elements plays a critical role in optimizing the cost of any project. As a result, this article breakdown everything you need to know about how much injection molding cost and how you can optimize it for your project.

Submerged arc welding is a standard industrial process wherein an arc is formed between a workpiece and an electrode. It was invented in 1935 by the E. O. Paton Electric Welding Institute in Kyiv, Ukraine as a driving force behind the Second World War. One of the most notable applications of this invention is the T34 military tank.

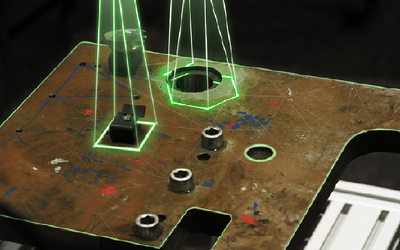

First article inspection (FAI) is a crucial step in the manufacturing process. The quality control (QC) team needs to optimize this phase of inspection in order to limit the back and forth between conception and fabrication. The QC team must not only correctly identify the defects, but also provide relevant data, measurements, and results for solving the identified problems.

Go green and save green with electric vehicles! Unlike traditional internal combustion engine (ICE) vehicles, electric vehicles run on batteries, cutting down on harmful greenhouse gas emissions and saving energy. While the initial cost may be higher, the long-term savings are worth it, especially as electric vehicles become more affordable and accessible.

Humans sharing a workspace and collaborating with robots has become a reality that companies and their smart factories just can’t do without, as it allows flexible manufacturing in variable batch sizes with maximum efficiency. In short, successful human-machine interaction is key for future-proof manufacturing.

Young Talent Square at Vision, Robotics & Motion 2023: Start-Ups and Student Teams Discuss Their Technologies

Vision, Robotics & Motion is a highly anticipated event in the manufacturing industry that will take place in the Netherlands on the 7th and 8th of June, 2023. It will celebrate its 20th edition in 2023.

Soldering Unveiled: Exploring Wave and Reflow Techniques for Engineering Graduates. Delve into the Depths of PCB Assembly, Component Compatibility, Production Efficiency, and Quality Assurance. Gain Profound Insights into Wave Soldering Machines, Reflow Ovens, and the Art of Soldering. Empower Your Engineering Journey with this In-Depth Comparative Analysis of Two Key Soldering Methods.