Tagged with

electronics

Latest Posts

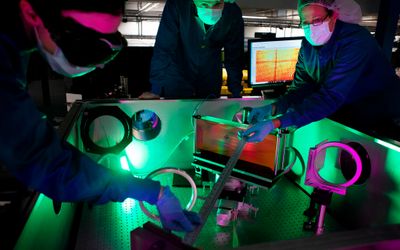

Researchers have designed smart, colour-controllable white light devices from quantum dots, tiny semiconductors just a few billionths of a metre in size, which are more efficient and have better colour saturation than standard LEDs, and can dynamically reproduce daylight conditions in a single light

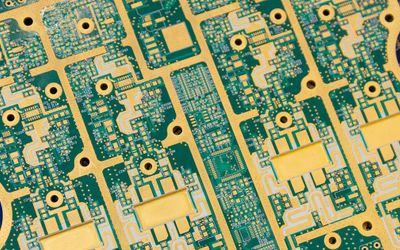

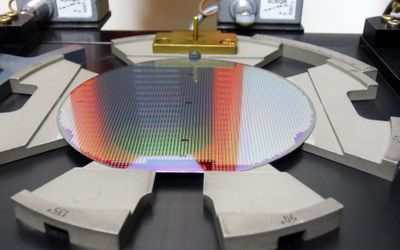

Wafer thinning is a part of the semiconductor manufacturing process. It is essentially grinding off the backside of the wafers to control their thickness and is useful for the production of ultra-thin wafers. These flattened wafers are used to effect stacked and high-density packaging in compact or microelectronic devices. This article discusses the meaning of wafer thinning, along with its various techniques and significance.