Tagged with

additive manufacturing

Latest Posts

Inkjet Printing for Solar Cell Manufacturing: How Electroforming is empowering the photovoltaics industry moving forward

Inkjet printing is an extremely versatile, non-contact process that involves jetting tiny ink droplets to facilitate direct printing. It has seen a surge of new applications in fields including electronics, life science, optics, and PV.

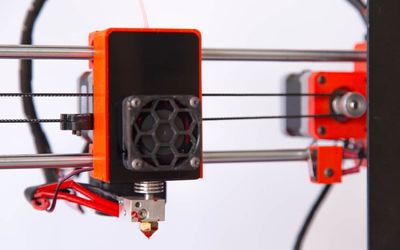

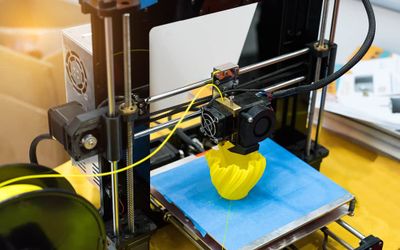

RMC Motorsport drastically reduces its production times and manufacturing costs by 3D printing end-use parts for their rally cars

RMC Motorsport, an automotive company dedicated to the rally sector, has internalized & optimized internal processes and achieved greater design capacity by involving 3D printing technology in the manufacturing process of their rally cars.

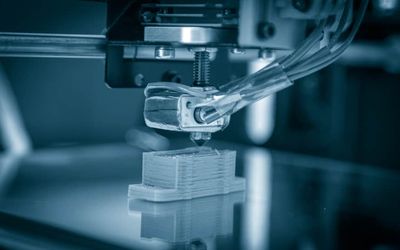

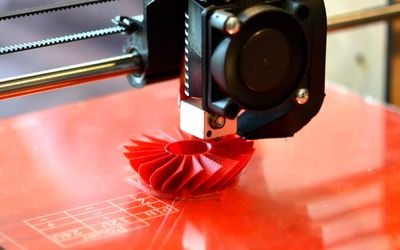

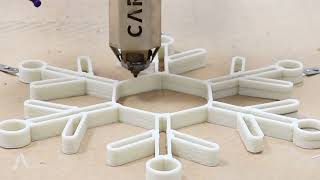

Although 3D printing was predicted to be more widespread than it has turned out to be, the technology is still undergoing enormous development. Senior Researcher David Bue is in charge of establishing DTU’s giant ‘3D printing playground’, where new records for miniature printing are currently being set.

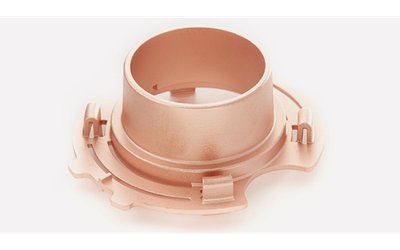

Electroforming is an additive manufacturing process specialized for the production of high precision metal parts. Its uniqueness is that you can grow metal parts atom by atom, providing extreme accuracy and high aspect ratios. Typical precision of a electroformed part goes down to 1 to 2 μm, which is beyond what most other manufacturing technologies can reach.