Tagged with

additive manufacturing

Latest Posts

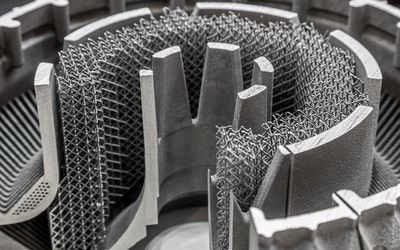

While industries like aerospace and automotive have been using additive manufacturing technologies for many years, the marine sector has recently picked up the pace of adoption thanks to the benefits provided by Large Format Additive Manufacturing. Companies like yacht and ship-builders are quickly speeding up the introduction of large parts manufactured with technologies like Caracol's Heron AM.

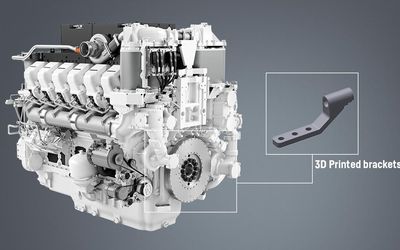

The military and defense sectors are undergoing an unprecedented transformation as military bases around the world adopt 3D scanning and additive manufacturing technologies for a wide range of applications. That includes maintenance, repair, and overhaul (MRO) processes, damage assessments and reverse engineering of parts, to name a few.

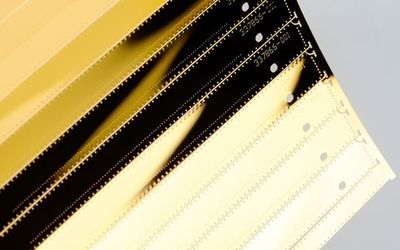

Inkjet nozzle plates are one of the most important components of inkjet print heads, as the quality of the nozzle plates directly determines the resulting printing performance of the whole system. This article introduces what an inkjet nozzle plate is, how this important component works, and how it is manufactured.

The beauty of additive manufacturing is in the flexibility these technologies provide in terms of scale, shape, and materials. Building know-how on software has allowed Caracol to leverage these skills and adapt them to working with robotics for LFAM on different processes - from its proprietary thermoplastic/composite pellet extrusion Heron AM to introducing Metal with WAAM.

In 3D printing, achieving consistent and high-quality prints requires more than just a good printer and filament. Calibration and quality control are essential components that can make or break your 3D printing experience. In this article, we will explore the importance of calibration and quality control through test prints of common shapes.