Tagged with

wearables

Latest Posts

Review of industrial applications of printed electronics - what are current successful applications?

TechBlick's presentation reviews printed electronics' industrial applications, dispelling the notion that it's solely a technology of the future. The talk showcases various commercial success stories incl. photovoltaics, displays, sensors, HMIs, 3D electronics, MLCCs, PCBs, semicon packaging, etc

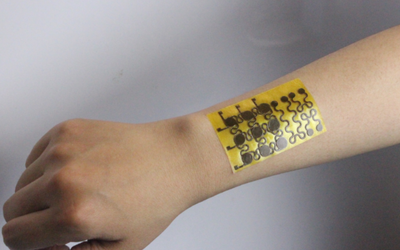

PCBA design capabilities are crucial to the future of wearable technology. Wearables and PCBA design are inextricably linked since both have a significant influence on each other. As wearable devices become more popular, electronics designers and manufacturers are designing smaller, denser, and more flexible devices.

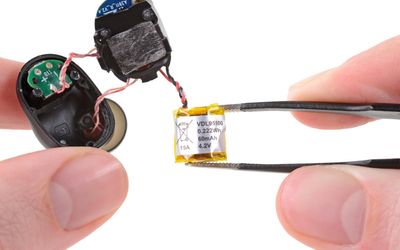

Extending the Battery Life of Hearables and Wearables with Single-Inductor Multiple-Output Switching Architecture

Article #5 of Power Management for Tomorrow’s Innovations Series: Single-Inductor Multiple-Output (SIMO) architecture enables design engineers to extend the battery life, and reduce the circuit board size for hearables and wearables

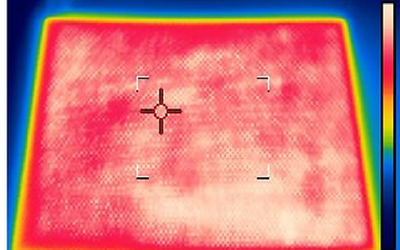

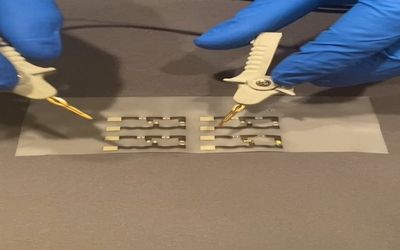

Wearable electronic textiles are a demanding environment for reliable interconnects – the ability to function with movement and survive multiple cleanings and reuse. Good adhesion is particularly challenging in these wearable and conformable electronics applications. While solders provide the most conductive electrical connection, they are rigid and require not only the addition of an underfill adhesive but usually a post bond encapsulation. This Anisotropic Conductive Epoxy, provides reliable interconnections between electronic components and circuitry on textiles with excellent structural bonding, without encapsulation, even under repeated stretching and washings. This technology has been shown as a scalable assembly process for e-Textile manufacturing in an SMT line.