Tagged with

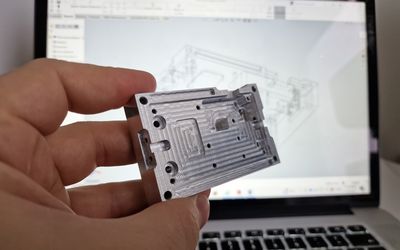

prototyping

Latest Posts

Once the first prototype of your IoT device becomes available, it is essential to start power profiling and estimating battery life. This process involves gaining a comprehensive understanding of the device's configuration and power consumption characteristics within its specific deployment context.