Tagged with

product design

Latest Posts

Sheet metal fabrication is a well-established production process used in manufacturing sheet metal parts. It involves using techniques such as bending, punching, cutting, forming, etc., to fabricate sheet metal. After producing a sheet metal part, depending on the use and other factor, the sheet metal part can be subjected to a post-processing stage by the application of sheet metal finishes.

Products made from ceramics have become part of man’s everyday life. Made traditionally using a kiln, this material finds application in the production of a wide range of optical, mechanical, and electrical appliances. Nonetheless, the current trend in ceramic product manufacturing is CNC machining.

Heat treatment processes involve precise heating and cooling procedures to change the physical and mechanical properties of metals. Generally, to alter undesirable properties and strengthen desirable ones. One such heat treatment process is annealing, which allows us to modify the mechanical characteristics of certain metals and alloys to better match their intended use.

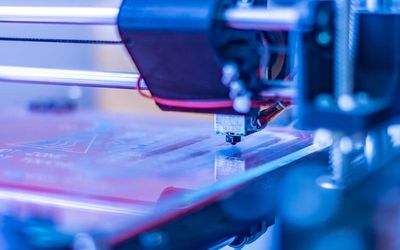

It’s hard to believe that 3D printing has only been around since the 1980s. This technique, also called additive manufacturing, has proved so immensely useful that it’s evolving very quickly. The process was originally devised to make prototypes for one-off or small-batch parts. Materials were added progressively to build up a solid object, based on 3D digital models. It was much more cost-efficient than cutting source materials down, as no waste was apparently produced.