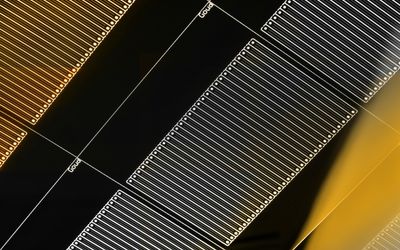

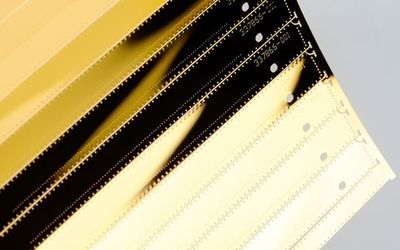

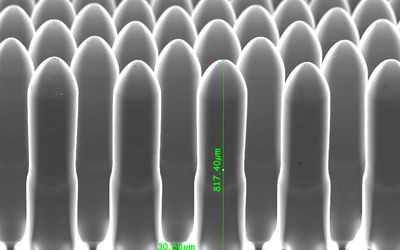

Pushing the Boundaries of Electroforming: Advanced Lithographic Electroforming and LIGA Processes explained

Compared with LIGA Electroforming technologies such as UV LIGA and X-Ray LIGA processes, Advanced Lithographic Electroforming is the most ideal process from prototyping to mass production.