Tagged with

manufacturing systems

Latest Posts

Sheet metal fabrication is a well-established production process used in manufacturing sheet metal parts. It involves using techniques such as bending, punching, cutting, forming, etc., to fabricate sheet metal. After producing a sheet metal part, depending on the use and other factor, the sheet metal part can be subjected to a post-processing stage by the application of sheet metal finishes.

The rapid evolution of 3D printing technology has made it faster, more automated and capable of greater production volumes. Developments have reached a point where the technology offers manufacturers significant production value. It means manufacturing costs can be significantly reduced in all aspects of manufacturing, all the way from R&D to actual production.

Products made from ceramics have become part of man’s everyday life. Made traditionally using a kiln, this material finds application in the production of a wide range of optical, mechanical, and electrical appliances. Nonetheless, the current trend in ceramic product manufacturing is CNC machining.

Heat treatment processes involve precise heating and cooling procedures to change the physical and mechanical properties of metals. Generally, to alter undesirable properties and strengthen desirable ones. One such heat treatment process is annealing, which allows us to modify the mechanical characteristics of certain metals and alloys to better match their intended use.

It’s hard to believe that 3D printing has only been around since the 1980s. This technique, also called additive manufacturing, has proved so immensely useful that it’s evolving very quickly. The process was originally devised to make prototypes for one-off or small-batch parts. Materials were added progressively to build up a solid object, based on 3D digital models. It was much more cost-efficient than cutting source materials down, as no waste was apparently produced.

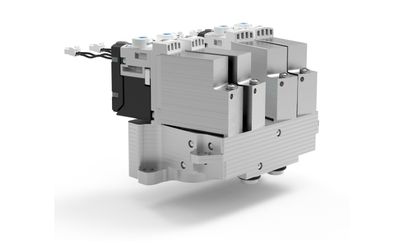

Online manufacturer supplies machined parts for prototypes resulting in significant time and cost savings

Festo relies on parts from Online Manufacturer FACTUREE to develop functional prototypes

Results Revealed and Facts Exposed: Benchmarking Two 3D Scanning Metrology Solutions to Save Inspection Time

More time—this is a luxury that many people wish they could afford. What about engineers who work long hours to design and manufacture molds to produce automotive performance parts, such as engine devices, transmissions, and electronic controls? What would they do if they could save 85% of the time required for mold inspections?

Mobile robots are becoming increasingly common in manufacturing facilities, as they replace human beings in repetitive transfer tasks. Most of them can be found in warehouses, but they’re also finding a place in assembly and manufacturing plants. This is mainly due to continuing developments in sensor technology, and computer intelligence. Their safety and flexibility have also improved.

Injection molding is an invaluable process for creating plastic parts. This process is fast, cheap, and helps create vast volumes of identical objects. One of the most significant advantages of injection molding is the natural surface finish of molded parts. Even without any injection molding surface finish or post-processing treatment, molded parts have smooth surface finishes suitable for many end uses.