Tagged with

Injection Molding

Latest Posts

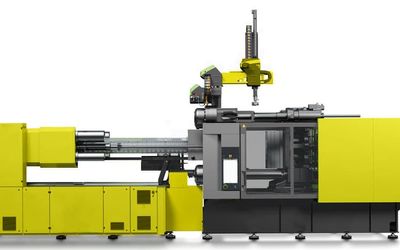

Injection molding is an invaluable process for creating plastic parts. This process is fast, cheap, and helps create vast volumes of identical objects. One of the most significant advantages of injection molding is the natural surface finish of molded parts. Even without any injection molding surface finish or post-processing treatment, molded parts have smooth surface finishes suitable for many end uses.

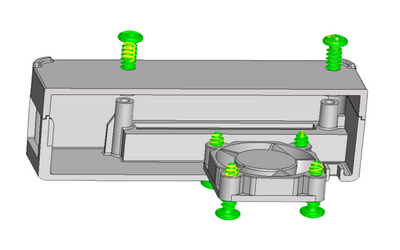

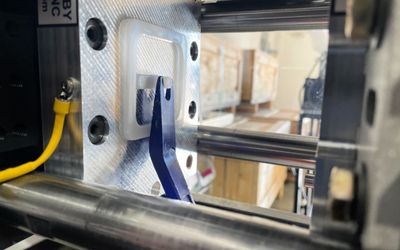

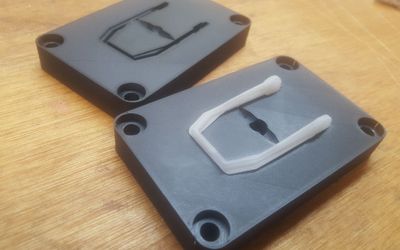

3D Printed Molds for Keychain Creation! Unlock your creativity with custom-designed 3D printed molds, crafted using the Form 3+ printer. Take it a step further with the APSX-PIM injection machine, which effortlessly injects a variety of materials into the 3D printed molds. From vibrant colors to durable materials, the possibilities are endless!

The injection molding cost is a common focus of plastic product manufacturers who use the process. It is an agglomeration of different factors and elements, and understanding such factors and elements plays a critical role in optimizing the cost of any project. As a result, this article breakdown everything you need to know about how much injection molding cost and how you can optimize it for your project.