Tagged with

electronics

Latest Posts

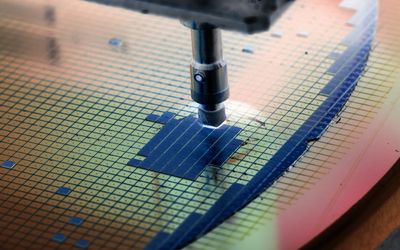

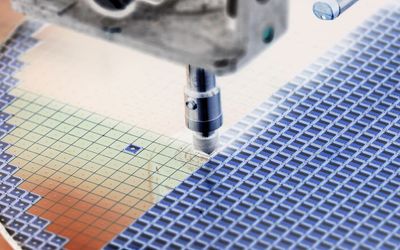

Wafer backgrinding is a crucial step in semiconductor manufacturing, as it prepares the wafer for further processing and packaging. The procedure comprises the thinning of silicon wafers by scraping out material from the backside, which is crucial for enhancing the functionality and dependability of semiconductor devices. This article examines the wafer backgrinding procedure, its difficulties, and the significance of quality control in ensuring the production of high-quality semiconductor devices.

Silicon, with its abundant availability and unique properties, serves as the fundamental building block for semiconductor manufacturing. Its semi-metallic nature makes it an ideal material for controlled conduction of electricity. Furthermore, the combination of silicon with oxygen produces silicon dioxide, a crucial insulating component in silicon chip manufacturing.

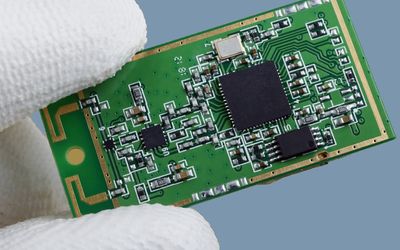

Die attach, also known as die bonding or die mount, is a process used in the semiconductor industry to attach a silicon chip to the die pad of a semiconductor package's support structure, such as a leadframe or metal can header. This article explores the fundamentals of die attach, its importance, materials, and methods used in die attach, its parameters, quality, and reliability techniques.

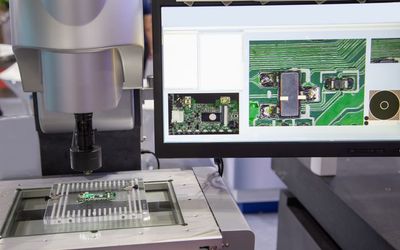

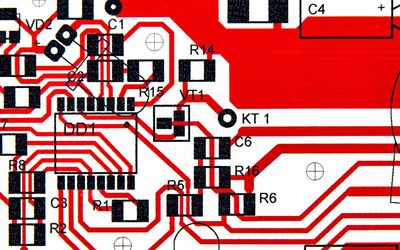

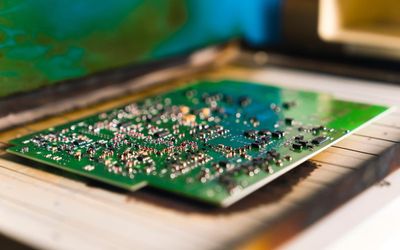

Soldering Unveiled: Exploring Wave and Reflow Techniques for Engineering Graduates. Delve into the Depths of PCB Assembly, Component Compatibility, Production Efficiency, and Quality Assurance. Gain Profound Insights into Wave Soldering Machines, Reflow Ovens, and the Art of Soldering. Empower Your Engineering Journey with this In-Depth Comparative Analysis of Two Key Soldering Methods.

Ladder Logic Programming provides a visual representation of electric circuits for designing and managing automated processes. With its roots in relay control systems, Ladder Logic brings simplicity and clarity to the digital world. Widely used in Programmable Logic Controllers, mastering Ladder Logic is essential for navigating and excelling in the automation-driven industrial landscape.

Surface profile or profile of a surface is a crucial component of material performance and affects many different sectors. Engineers and researchers can optimize material qualities, improve product performance, and guarantee the durability of components by having a full understanding of surface profile. The foundations of surface profile, its significance, and its applications in many industries will all be covered in detail in this comprehensive guide.