Tagged with

electroforming

Latest Posts

when to choose Electroforming over traditional manufacturing methods: a cost-effectiveness perspective

This blog will explore when Electroforming might be the most cost-effective choice, compared to 3D Printing, Laser Cutting, Stamping, Chemical Etching, and Electroplating.

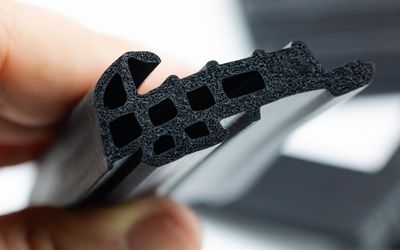

Applications of Electroforming: why Electroforming is the ideal solution for manufacturing optical parts

Electroforming technology has emerged as the most suitable method for manufacturing high-quality optical parts due to its unique combination of high precision, material properties, and design flexibility.

Electroforming for Engineers: overcome R&D challenges by co-engineering with Electroforming technology

Electroforming provides a pathway to overcoming fabrication challenges, empowering R&D engineers to reach past the limits of conventional manufacturing processes. To fully leverage Electroforming technology and engineering creativity, Veco provides a co-engineering service to empower the engineers.

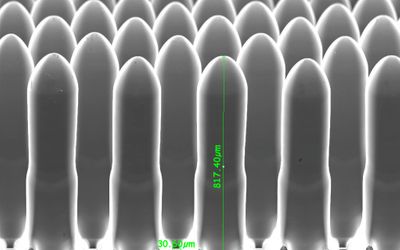

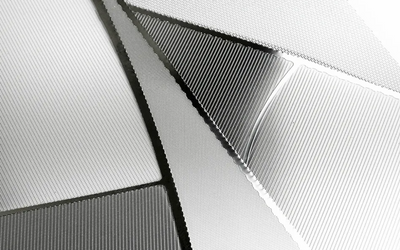

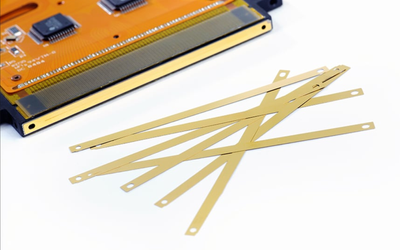

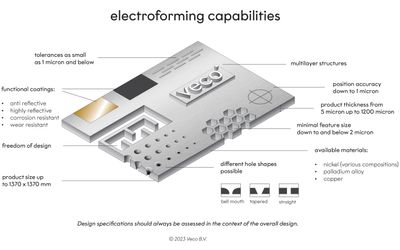

Electroforming is an Additive Manufacturing process specialized for the production of high-precision metal parts. Nickel, due to its expansive range of mechanical properties, aesthetic appeal, and resistance to corrosion, has become the most widely used material for this process. It not only enables the reproduction of extremely fine details but also permits the deposition of materials with high hardness. Electroforming technology allows depositing metal alloys to tailor specific material properties like mechanical or thermal characteristics.

Veco’s unique Advanced Lithographic Electroforming process also referred to as Advanced Photo Electroforming, promises a move towards the frontier of precision engineering, incorporating micro precision, complex features, and freedom of design, all of which empower next-gen innovations across industries facing the challenge of miniaturization. This blog introduces 5 reasons to choose Electroforming in terms of freedom of design.

Pushing the Boundaries of Electroforming: Advanced Lithographic Electroforming and LIGA Processes explained

Compared with LIGA Electroforming technologies such as UV LIGA and X-Ray LIGA processes, Advanced Lithographic Electroforming is the most ideal process from prototyping to mass production.