The acceptance of plastic machining as a manufacturing process is due to the wide array of plastic CNC materials available. Furthermore, with the introduction of computer numerical control, the process becomes more accurate, faster, and suitable for making parts with tight tolerance. How much do you know about plastic CNC machining? This article discusses the materials compatible with the process, available techniques, and other things that can help your project.

Tagged with

cnc milling

Latest Posts

Online Manufacturer supports assembly work at the world's largest stellarator fusion reactor with CNC-machined special parts

FACTUREE supplies components for fusion research facility at the Max Planck Institute for Plasma Physics

In this article, we will delve into the diverse world of CNC materials. We will provide you with a comprehensive guide to selecting the right materials for CNC machining, including a detailed list of commonly used materials. Additionally, we will touch on some lesser-known materials that you may not have considered before.

The surface finish is an integral part of the CNC machining process because a lot of applications require both aesthetic and functional design. Modern industrial designers have all the right tools and checks to ensure that their designs are functional. So, CNC machining surface finishes is an area where they can cause their product to stand out from the crowd.

Online Manufacturing of special parts adds benefits for textile manufacturers such as quick availability

Freudenberg Performance Materials, a leading global developer and manufacturer of innovative technical textiles, explores new paths with its procurement of components. In this endeavor, the company has chosen FACTUREE – The Online Manufacturer as its supplier for various parts, including cut and bent sheet metal parts.

Computer Numeric Control (CNC) Machining is one of the most popular manufacturing techniques that use automated tools to generate the needed shapes and parts. What is CNC machining or how it works is a common question that anyone associated with the industry should know about. The following text will take a look at the basics of CNC machining and briefly discuss its major applications across different industries.

RPWORLD provides custom rapid prototypes and volume parts that can meet your precision requirements on complex geometries structure. No matter you need 1 or 10,000+ parts, or the metal part is as precision as ±0.01, the reliability and consistence of metal parts by CNC Machining of RPWORLD is what you can rely on.

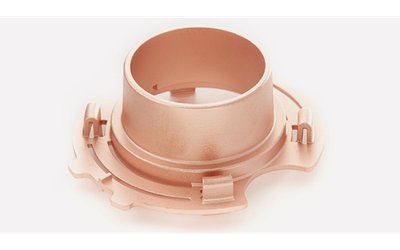

The client is a well-known automotive company. They developed a new headlights, and then come to RPWORLD for high quality aesthetic model. The mold is used for appearance reviewing and lighting testing, which sets high process standard for after treatment. what’s more, the lead time for this project is 20 calender days.