Tagged with

additive manufacturing

Latest Posts

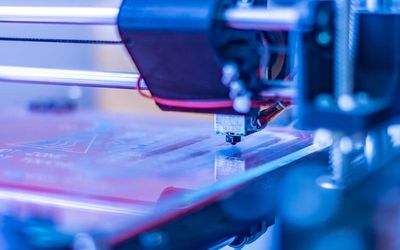

It’s hard to believe that 3D printing has only been around since the 1980s. This technique, also called additive manufacturing, has proved so immensely useful that it’s evolving very quickly. The process was originally devised to make prototypes for one-off or small-batch parts. Materials were added progressively to build up a solid object, based on 3D digital models. It was much more cost-efficient than cutting source materials down, as no waste was apparently produced.

Carbon fiber is one of the most powerful materials for anyone trying to get the most out of 3D printing. But when should you use it, and what applications can you use it for? Let’s delve into these questions and discover why 3D printed carbon fiber composites are more accessible and versatile than ever before.

Veco’s unique Advanced Lithographic Electroforming process also referred to as Advanced Photo Electroforming, promises a move towards the frontier of precision engineering, incorporating micro precision, complex features, and freedom of design, all of which empower next-gen innovations across industries facing the challenge of miniaturization. This blog introduces 5 reasons to choose Electroforming in terms of freedom of design.

The renowned technology enterprise Zeiss is at the forefront of the optics industry by using 3D printing to create customized parts for its microscope in serial production. This article explores how this innovative solution has significantly improved the manufacturing process, resulting in substantial time and cost savings for the company.

How 3D printing is enabling faster design, higher productivity, and more customization in manufacturing

Introducing the first article in a new series, making clear the impact of additive manufacturing on Manufacturing, Transport, Packaging, and STEAM. In this article, we're zooming in on Manufacturing.