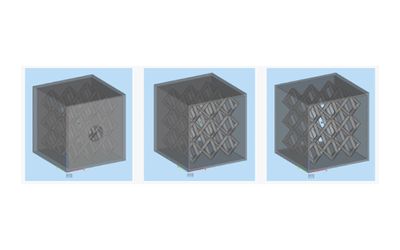

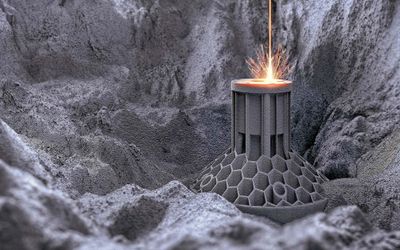

A powerful and versatile tool for engineers and 3D printing projects. Not only do lattice structures help make parts lighter and stronger, but they can also help reduce part volume, leading to fewer surface defects and excessive stress buildup. Learn how to use lattice structures in your 3D-printed parts without making a mesh of things with our design tip!

Tagged with

additive manufacturing

Latest Posts

Electroforming is an Additive Manufacturing process specialized for the production of high-precision metal parts. Nickel, due to its expansive range of mechanical properties, aesthetic appeal, and resistance to corrosion, has become the most widely used material for this process. It not only enables the reproduction of extremely fine details but also permits the deposition of materials with high hardness. Electroforming technology allows depositing metal alloys to tailor specific material properties like mechanical or thermal characteristics.

The Roll-to-Roll (R2R) Process in Industrial Scale-Up: A Comprehensive Examination of Its Impacts and Challenges

Organic Photovoltaics (OPV are a 3rd Gen PV technology with unique attribute. The key to their success is in Roll-to-Roll (R2R) processing. Here you will learn about the advantages and challenges of R2R manufacturing in OPVs and printed electronics

Hands for Ukraine: The Victoria Hand Project's 3D Printing Initiative to Democratize Access to Prosthetic Care in Ukraine

In a world often defined by disparities in healthcare access, Victoria Hand Project, a Canadian charity, is a beacon of hope. Founded in 2015 with the mission to provide accessible 3D-printed prosthetic care to under-resourced communities around the world, Victoria Hand Project has transformed lives by combining cutting-edge technology with compassionate outreach.