Category

materials

Latest Posts

Products made from ceramics have become part of man’s everyday life. Made traditionally using a kiln, this material finds application in the production of a wide range of optical, mechanical, and electrical appliances. Nonetheless, the current trend in ceramic product manufacturing is CNC machining.

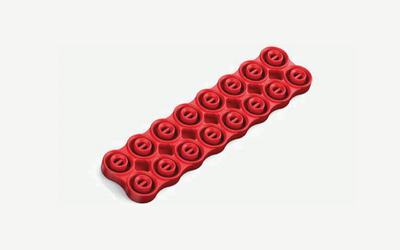

Injection molding is an invaluable process for creating plastic parts. This process is fast, cheap, and helps create vast volumes of identical objects. One of the most significant advantages of injection molding is the natural surface finish of molded parts. Even without any injection molding surface finish or post-processing treatment, molded parts have smooth surface finishes suitable for many end uses.

Sheet metal fabrication is the process of turning flat sheet metals, typically 0.15 mm to 10 mm thick, into parts and structures of various shapes. The stock materials for this process are flat metal sheets. Sheet metal fabrication is used to create objects such as enclosures, chassis, brackets, stamped features, curls, etc. It is also used for decorative purposes to make patterns in metal sheets.

Steel is an alloy of iron and carbon and a basic part of industries such as construction and the military due to its strength, durability, customizability, and quick fabrication. Of the several types of steel available in the market, the alloy steel vs stainless steel comparison is one of the many comparisons common among manufacturers who want to work with steel.

Lightweighting materials play a crucial role in offering the potential for improved fuel efficiency, enhanced performance, and reduced emissions in the automotive industry. It is anticipated that the lighter and more efficient automotive materials and components will revolutionize the industry in the coming years.