KyronMAX® Challenge Community Vote Winner: Path to prototype design log

KyronMAX Challenge Community Vote Winner Design Log. This evolving article documents the process of Daniel Scott Mitchell, and Farbod Moghaddam as they work closely with Mitsubishi Chemical Advanced Material engineers to develop their unique lacrosse head design.

The Mitsubishi Chemical Advanced Materials KyronMAX® Challenge invited designers and engineers to share designs that utilized KyronMAX®'s range of high-strength carbon fiber-based composites to solve an engineering or manufacturing challenge. The overall winner received $25,000 in support to develop their design. The Wevolver community selected the community winner who received $10,000 in support. For more information about the challenge and the KyronMAX material, see our previous articles in the series.

The winner of the KyronMAX Challenge Community Vote was the High-Performance Lacrosse Head designed by Daniel Scott Mitchell and Farbod Moghaddam. Their goal? To make one of the lightest, strongest, and most durable lacrosse heads on the market.

Lacrosse is a popular physically intense game from the United States where players use a stick with a catching head to carry, pass, catch, and shoot the ball into the opposition’s goal. The lacrosse head must endure a variety of forces throughout a game (see below for a small taste) often in extreme temperature environments posing a significant engineering challenge.

Daniel and Farbod are now working closely with Mitsubishi Chemical Advanced Material engineers to develop and produce a full prototype of the head. This article will be updated monthly to provide insight into the design development and manufacturing process.

In addition to this log, the team will be looking for engagement with lacrosse players to provide input and text resulting prototypes. So, if you are interested in taking part in the development of a game-changing lacrosse head, make sure to follow Daniel and Farbod on their journey on Wevolver and their personal social media accounts: Daniel - Twitter: @TheDanielMitch | Instagram: @danielscottmitchell and Farbod - Twitter: @FarbodTheMogh | Instagram: @farbod_moghaddam.

Stage One (May-June): Engineering validation

- Utilizing feedback from the community to develop the first prototype.

- Working with the MCAM team to determine the best prototyping approach for prototype units (most likely additive manufacturing)

- Use testers to validate the engineering approach.

- Research potential funding opportunities (crowdfund, VC, retail, etc.).

Stage Two (June-July): Design validation

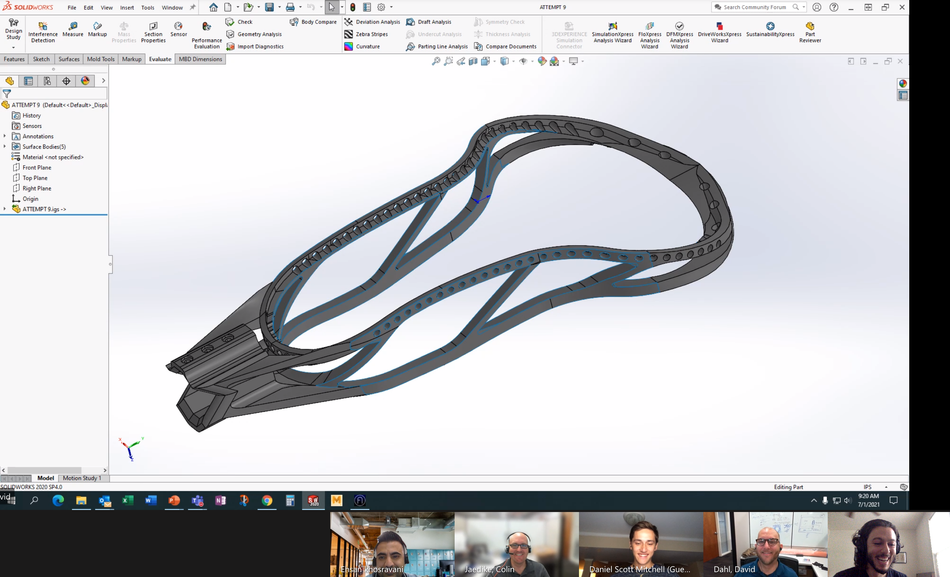

The Community Vote winners have been working hard to refine their design and get feedback from MCAM engineers.

The last month has been spent:

- Finalizing the prototype manufacturing process

- Fixing the 3D design

- Troubleshooting the file conversions to open the files in SolidWorks

The team faced some challenges with their design files. They had been working with the Fusion360 computer-aided design software whereas MCAM uses the industry-standard Solidworks. There has been some back and forth troubleshooting file conversions and corruptions. To make it easier the model may be remade in Solidworks.

The next stage of the process will be to print a prototype. This prototype, likely created using SLA 3D printing will allow Daniel and Farbod to test the geometry of the design and check whether the lacrosse head fits well with conventional shafts, can be fitted with standard stringing & netting, and provides the right look and feel.

This prototype won’t have the structural strength to test at full pace but the team will be working closely with professional lacrosse players and other members of the lacrosse community to get feedback on the design.

If no major changes to the design geometry need to be made, the next step after the validation of the 3D-printed prototype is to start producing lacrosse heads using the KyronMAX material! Farbod, Daniel, and the Mitsubishi team are gearing up to produce those prototypes soon after the design geometry is finalized.

How can you help?

The lacrosse head still needs a name. Daniel and Farbod are asking the Wevolver community to help select a name for their design. Have an idea? Either email Daniel at dsmitchell98(at)gmail(dot)com or follow Wevolver's social media posts and comment with your ideas!

Stage Three (July-August): Production validation

- Choose business model and brainstorm marketing strategies.

- Determine the best material to use based on suggestions from MCAM engineers.

- Make minor design changes if necessary based on Beta feedback.

- Converge on final material selection.

- Finalize business launch plans.

- Create production-quality products that are ready for release.

We will be updating this article as the team makes progress. Follow along here and on our Instagram.

About the sponsor:

Mitsubishi Chemical Advanced Materials is a leading global manufacturer of high-performance materials in the form of semi-finished products and finished parts. The company has locations in 20 countries and more than 2,800 employees. Its specialty engineering thermoplastics and composites are superior in performance to metals and other materials and are used in a wide range of applications, primarily in the capital goods industry. The company is continuously developing new areas of applications in close cooperation with industry leaders in a broad variety of customer markets. The Mitsubishi Chemical Advanced Materials Group is well prepared to further expand its market leadership position.

Supporting the vision of our holding company, Mitsubishi Chemical Holdings Corporation (MCHC), Mitsubishi Chemical Advanced Materials is committed to the realization of KAITEKI, “a sustainable condition which is comfortable for people, society and the Earth”. To realize this vision, the MCHC Group engages in corporate activities that provide products, technologies and services based on the comprehensive capabilities of the Group in the Performance Products Domain, Industrial Materials Domain and Health Care Domain, with chemistry as the basis of our activities. We jointly express and promote our commitment under the corporate brand THE KAITEKI COMPANY.