Impact Footwear Brings to Market Customizable Flip Flops in Under 12 Months Using Design Automation & Architected Materials

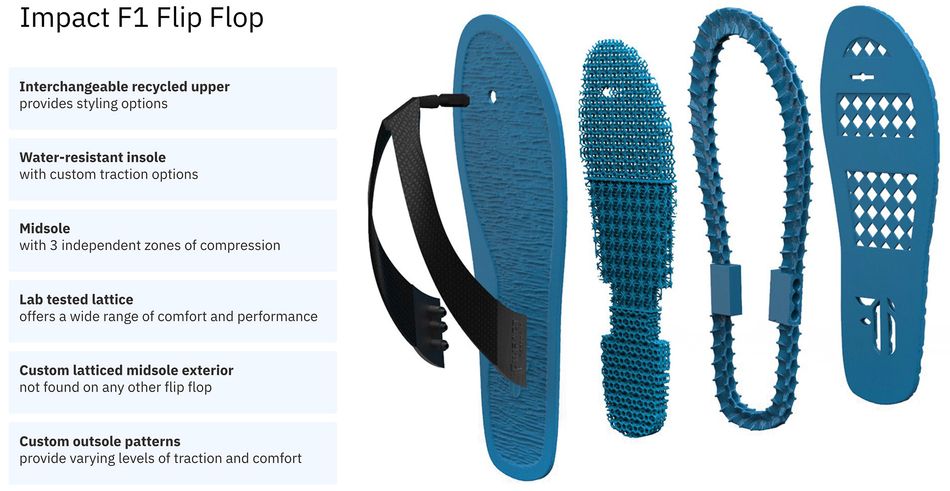

Impact Footwear is a startup that developed the first customizable flip flop sandal with three different pressure zones that is manufactured-on-demand with SLS 3D printing.

This article was first published on

ntopology.comMass Customization of Consumer Products

When Craig DeMerit, the founder of Impact Footwear, started working on developing his business idea he had a clear goal: to create customizable flip-flop sandals that were easy to personalize for the consumers and that are manufacturable on-demand with as little human intervention as possible. He had a general technical background and deep knowledge of the retail market, but zero experience in CAD or mechanical design. Twelve months later, his product was ready to hit the market.

Mass customization of consumer products is a challenge that many have attempted to achieve. Yet, developing a business model that can scale in an economically feasible way is not an easy task. Impact Footwear may be one of the first to crack the code of mass customization for retail applications.

Their approach takes advantage of the latest developments in manufacturing and design automation. The team fully automated the design and order placement processes to minimize operational costs. Also, they developed foam-like lattice structures that mimic the properties of traditional footwear materials. Finally, they leveraged Additive Manufacturing to minimize inventory and stay flexible in the product development process.

The advanced modeling capabilities of nTopology and the programmatic interface of nTopCL played a critical role in the development of this new product. In this case study, we describe how Impact Footwear took advantage of these capabilities to inspire you to apply them in your own process.

The World’s First Customizable Flip-Flop

It is no surprise that success stories of mass customization from the consumer retail industry are rare. There are supply chains, logistics, and design challenges that need to be accounted for long before launching a product into the market. Not to mention, making sure it is economically viable.

Since each product is unique, the manufacturing costs of each unit are significantly higher than the unit cost of mass-manufactured products. From a consumer’s perspective, a higher price point can be acceptable as long as they receive enough added value in return.

For Impact Footwear’s flip flops, this added value comes in the form of the 30 design variables that are populated based on the user’s input. Using a web-based configurator, customers can select from a variety of options that affect both the aesthetics and functionality of the sandal. For example, they can choose size and color, apply a label, but also select the pattern of the insole, the style of the midsole, and the traction texture of the outsole.

The most unique customization option offered by Impact Footwear is the ability to specify a different stiffness level for each of the three zones of the sandal — the toe, the arch, and the heel.

Since the whole sole is 3D printed from the same material, Impact Footwear is achieving this effect by applying lattice structures to the sandal’s midsole. The result is a high-durability flip flop that users can customize to fit their lifestyle.

Developing Foam-Like Lattices

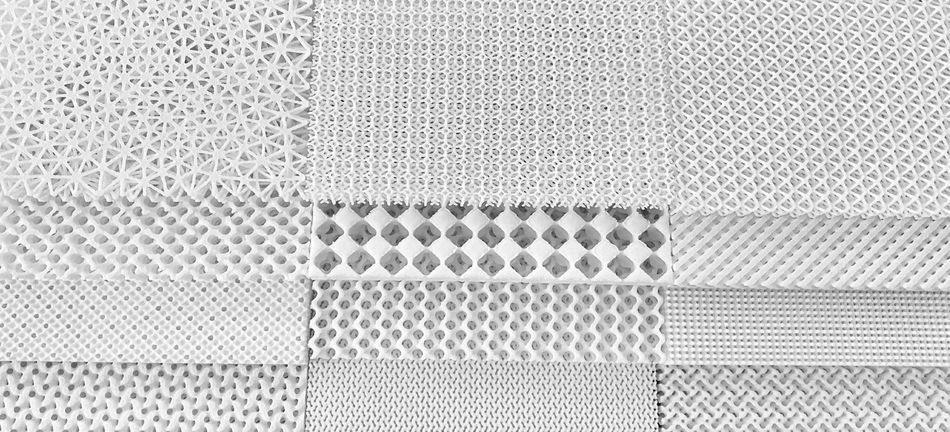

Impact Footwear lab tested 15 different lattice structures to identify designs that have equivalent properties with traditional materials used in the footwear industry today. The goal was to create architected materials with the same compression characteristics as gel foam, EVA foam, injected rubber, sheet foam, and hard plastic. By closely controlling the structure of the lattice, Impact Footwear was able to alter its material response.

The logic behind this design decision was simple. The only SLS 3D printing material suitable for this application is TPE, but it is still too stiff in its rigid form to feel comfortable to wear. Moreover, using multiple manufacturing processes was out of the question. One of the key design requirements was to be able to manufacture the entire sole as one piece to eliminate the costly manual assembly and gluing steps. Creating architected materials based on TPE was the answer.

Architected materials fundamentally change the flow of the product development process. Traditionally, the material properties are given and cannot be altered. With architected materials, you have the flexibility to change the behavior of the product just by altering its structure. This allows you to adjust to new information and changes to design requirements later down the line or — in the case of Impact Footwear — customize your products to the specific needs of the user.

The advanced latticing capabilities of nTopology unlocked this option for Impact Footwear. By being able to generate a new lattice structure in seconds and visualize it 9x times quicker than with competing latticing software, their design team was able to test new ideas at an accelerated pace and iterate faster.

Designed on the Cloud

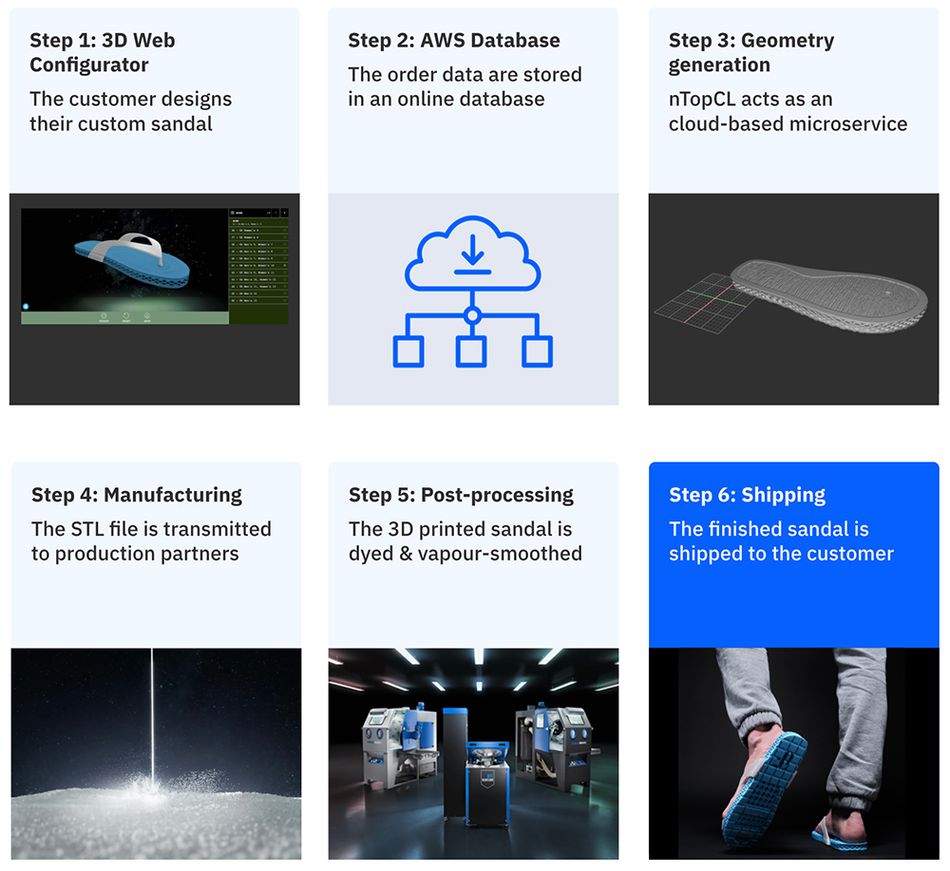

If done manually, it would take at least 1 hour per sandal for a designer to prepare and process every new incoming order. The additional time and operating cost that this would add to the production process would push the price of the sandal to an unreasonably high level.

Instead, Impact Footwear opted to create a fully automated and scalable design generation and order placement system. In fact, all the steps of the process are completely hands-free: from receiving the order, to generating the new design, to sending it to the manufacturer to produce on-demand.

This way, Impact Footwear created an expandable, scalable system that can handle any number of incoming orders — whether they receive 100 or 5,000 new orders per day — freeing up time for the small startup company to focus on other aspects of the business, like marketing and quality control.

The entire process runs on the cloud. In its heart lies the design automation capabilities of nTopCL. nTopCL is the command-line interface of nTopology that allows users to run nTop design workflows using scripts without opening the user interface of the main software. In this case, nTopCL acts as an advanced geometry computation microservice on the cloud.

Every time a new order is received, it triggers a Microsoft SQL Server script that calls nTopCL commands. Using the order specifications as input, the script reruns the nTopology design workflow that generates the custom design. An STL file is produced and then forwarded to the manufacturer. The manufacturer then 3D prints and post-processes the sandal and sends it to the customer. Within a day of placing the order, the product is 3D printed and it is ready for shipment to the customer the next day.

A key enabler of this fully automated system that Impact Footwear created was nTopology’s unmatched speed. Early on during the development process, Impact Footwear tested other similar tools. However, it took more than 90 minutes to process a new design and generate an STL mesh. In nTopology, generating a production-ready STL file takes less than 10 minutes.

Why nTopology?

nTopology was not the first design software that Impact Footwear tested in their development process. We asked Craig DeMerit why they chose nTopology and nTopCL as their software solution. Here are his answers:

Ease of use

“I have a general technical background, but I had zero CAD experience before starting this business. We needed a solution that was user-friendly and a 3D design novice like me could use. nTopology definitely met this requirement.”

Lightning speed

“In the other software that we tested, it took more than an hour to generate the final mesh. That was certainly not going to work from a commercial perspective since we wanted to generate thousands of designs per day. But it also meant that design iterations took a lot of time. nTopology delivered in both of these needs.”

Multiple File Formats

“In our design process, we are using both STEP files and some stylized parts that are meshes. We needed a product that could import both and use them equally throughout the process.”

Extendable Workflows

“We needed to be able to create design processes that are reusable, easy to maintain, and that can pass parameters between each other — not only for this product but also future products we are planning to develop. nTopology’s custom blocks enabled us to do this.”

Programmatic Interface

“Having an easy way to input variables was extremely important for us. We also needed to be able to integrate into a programmatic environment and process the design without any intervention. Having a command line that utilizes JSON was extremely important.”

Lattice Structures & Surface textures

“Creating and manipulating unique lattice structures was one of the core requirements. We also needed to generate and apply surface textures. We found that nTopology really was the leader in this space.”

Labeling & Serialization

“We felt that adding a label was a great customization opportunity for individuals to put their mark on things. We also needed a way to add a unique identifier to the products, to be able to separate and ship them in a commercial way.”

The Next Steps

Impact Footwear launched its first product, the Impact F1 Flip Flop, in March 2021 in a crowdfunding campaign. Their 3D customization web tool is already live on their website. Moving forward, the team will continue to use nTopology to develop new surface textures and lattice designs to improve their sandals, create seasonal promotions, and expand their product range.

This case study was first published on the nTopology blog.