How Strong is a Space Wrench? Finite Element to Failure: High-Performance, Real-World Parts

The founding mission of polySpectra is straightforward: to create engineering-grade materials for additive manufacturing that help designers, inventors, and engineers make their ideas real.

This article was first published on

ntopology.comThe founding mission of polySpectra is straightforward: to create engineering-grade materials for additive manufacturing that help designers, inventors, and engineers make their ideas real. That last word is really key for us. We only focus on what’s real, what’s possible; and if it’s not possible today, we focus on how to make it possible tomorrow.

Introduction to polySpectra

At polySpectra our focus is, of course, materials. That’s what we do, it’s who we are. But those materials don’t exist in a bubble. Whether they’re used for electrical connectors or to create a wrench for use in space (more on that later), materials like our COR Alpha need all the right properties. While we have proved out material properties like mechanical isotropy, there’s obviously a huge difference between what we can prove in a lab and what happens when materials are out in the world.

When it comes to high-performance parts for the aerospace industry, additive manufacturing is making huge headway. As aerospace engineers continue to look more closely at bringing 3D printing to their real-world (and out-of-this-world) applications, failure isn’t an option. Nothing says “mission-critical” more than aerospace. It’s with that in mind that we’re setting about to understand — and to help you understand — when and how to work with 3D printing.

_The SpaceWrench

Our CEO, Raymond Weitekamp, recently shared a look into Finite Element to Failure: Simulation and Experimental Fracture Analysis of Lightweight Aerospace Components. The webinar — with its more digestible subtitle of “How Strong is a Space Wrench?” — is available to watch on-demand. Whether you’re an aerospace engineer, DfAM lead, or just someone who likes watching things break, this easy-to-follow talk digs into how nTopology can be used to set up a Finite Element Analysis (FEA), as well as how to interpret the results in the context of real-world materials failure

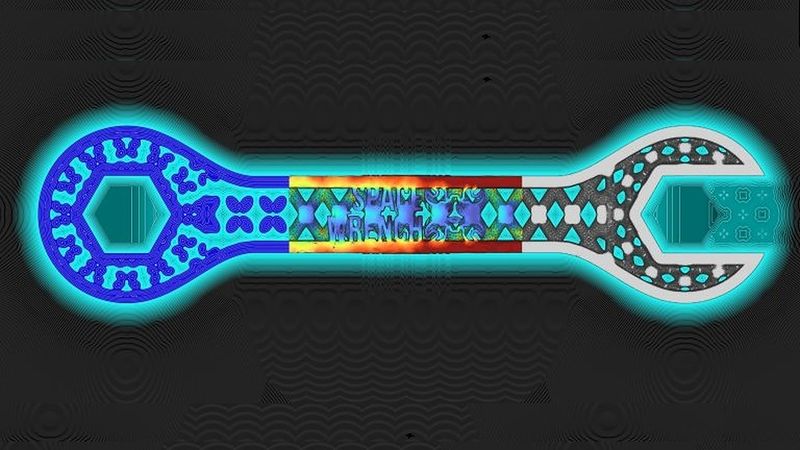

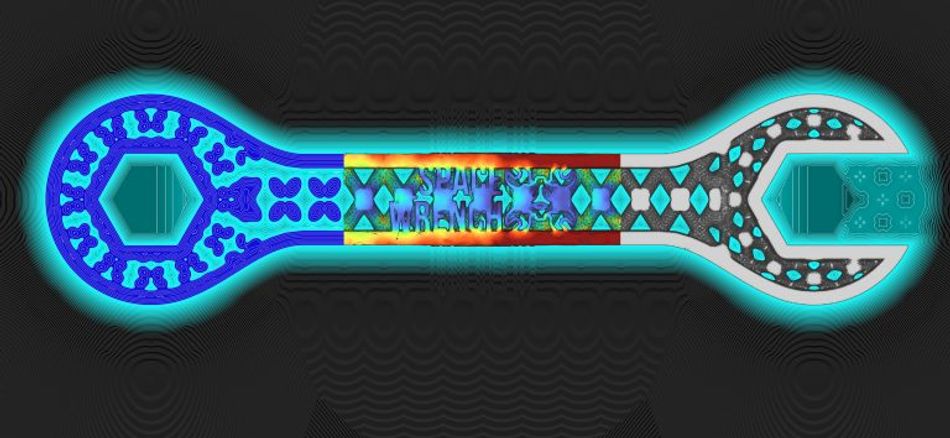

Because we can’t talk about most of the actual work we do — thanks to NDAs and top-secret projects — we set out to invent a functional object that would demonstrate the power of implicit design in combination with high-performance, engineering-grade materials. We invented a space wrench. A space wrench? A space wrench. We designed the _SpaceWrench to showcase lightweight lattice structures that are possible with nTopology design and highlight the mechanical performance of these intricate structures when 3D printed from COR Alpha.

But to actually understand the limits of these capabilities, we needed to break it. When a friendly SpaceX engineer asked how strong the wrench actually is, we set out on a mission to find out.

Finite Element to Failure

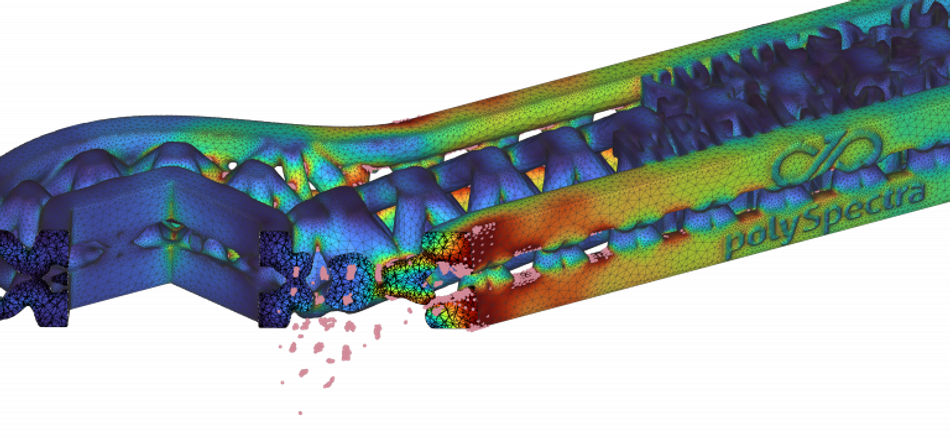

First, we ran the simulation. We input all the design and material attributes into nTopology FEA. In the webinar, Raymond runs through a few key points:

- How to set up a Finite Element Analysis in nTop

- Designing and analyzing our lightweight aerospace component entirely in nTop

- How to interpret the results in the context of real materials

- How to traverse the “valley of death” between simulation and experiment

- How strong is the _SpaceWrench?

Finite element analysis experiment to failure of the _SpaceWrench in nTopology

Finite element analysis experiment to failure of the _SpaceWrench in nTopology We don’t want to give away the ending, so you’ll have to check out the webinar to see Raymond run from simulation to experimental failure. What we can say is that when we tested the strength of the _SpaceWrench, we found a very strong correlation between simulation and experiment.

But why does that matter?

It’s just a simulation. From our experiments, though, we can extrapolate some important takeaways. First, we can distinguish between stress- and strain-dominated failure modes, to observe the practical importance of using tough materials. This type of testing can help us find specific use cases where COR Alpha can serve as a metal replacement for lightweight aerospace components. We can extend this analysis to build our design allowables for direct 3D printing of production parts. As an example, we define the max torque of the _SpaceWrench, to directly answer the question that prompted this exploration.

polySpectra specializes in implicit design using nTopology. Our design team has built up expertise in lattices, lightweighting, and triply-periodic structures. Our materials team brings a deep knowledge of chemistry and materials science to our design analysis. As a company, we have five years of experience in testing the thermomechanical, biological, and dielectric properties of production-grade additive materials. We understand that failure mode analysis is an important aspect of product design. That point of failure, like for the _SpaceWrench, isn’t a stopping point: it shows us just how far we can go with advanced design and true engineering-grade materials.

This article was first published on the nTopology blog.