Functional Optimization Of Mouse Traps

What to do when an apartment is infested with pests, when rows of ants march across windowsills and mice have taken refuge in the basement? It is lucky that there are companies out there that can help you with their products.

What to do when an apartment is infested with pests, when rows of ants march across windowsills and mice have taken refuge in the basement? It is lucky that there are companies out there that can help you with their products.

One of these companies is Orma. Orma relied on Steelte to make functional changes to an existing product to create an optimized safe bait distribution system for rodents.

Steelte srl is a recently founded Italian startup that works primarily in the automotive and mechanical sectors. Its main line of products is made up of milled products, FFF additive 3D printing, planning services, dimensional controls and reverse engineering.

Product optimization

The task was to update the distribution design and develop a new version, with better performance for the user and optimization for printing. Updating the design was necessary to incorporate the numerous changes made on the product over the course of time, changes that were not reported correctly in the technical drawings from the time. Next, starting from the updated project, a new version was designed according to the standards requested by the customer. In particular, Steelte provided the following services to Orma:

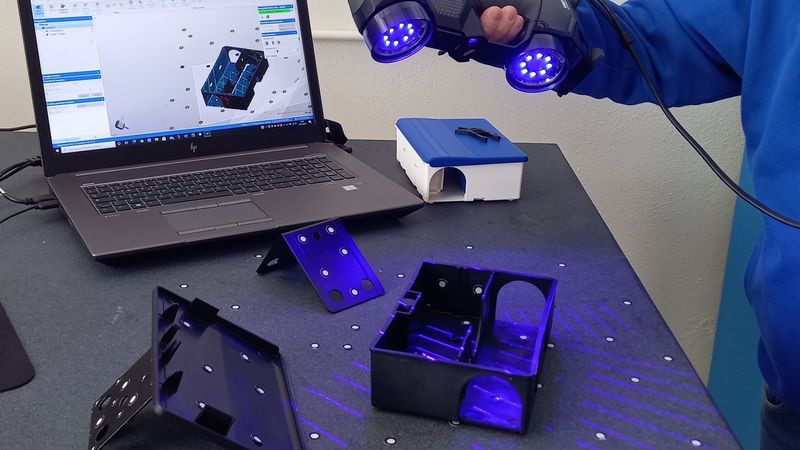

- scanning of the existing mouse trap with the HandySCAN 3D and Vxelements acquisition software by Creaform

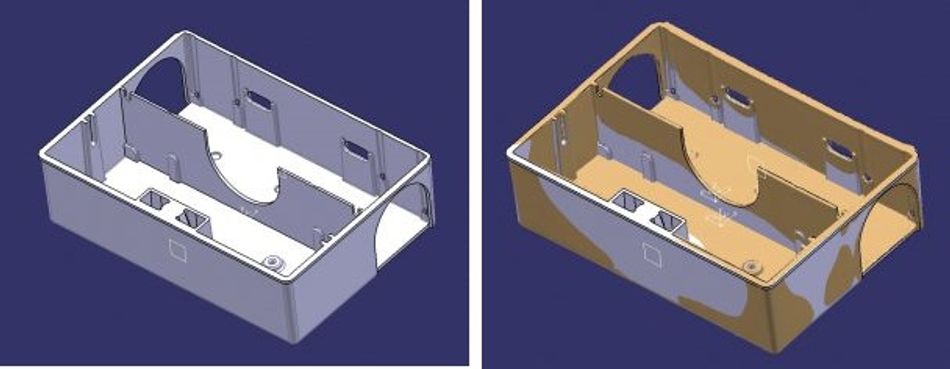

- Reverse engineering

- 3D modeling to correct some manufacturing errors

- Insertion of the customer’s requested functional changes and reconstruction of a CAD model for a new mouse trap in the CATIA V5 software by Dassault

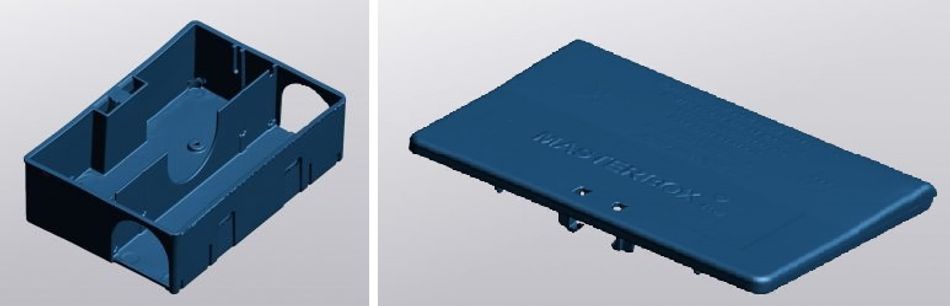

- Prototyping through 3D FFF printing

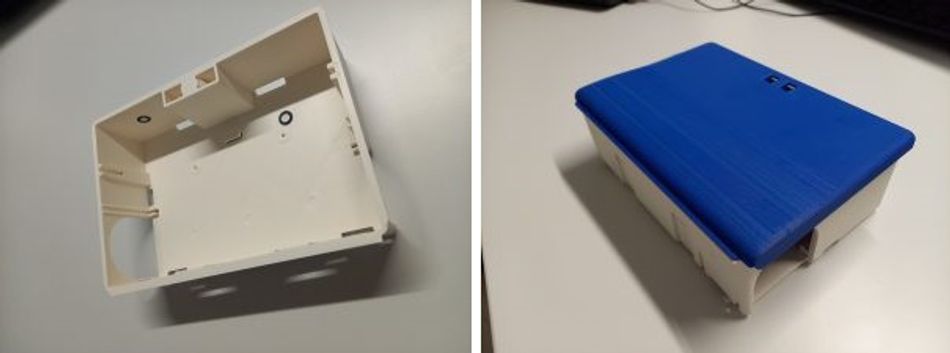

Trappola per topi stampata in 3D con e senza coperchio

Trappola per topi stampata in 3D con e senza coperchio

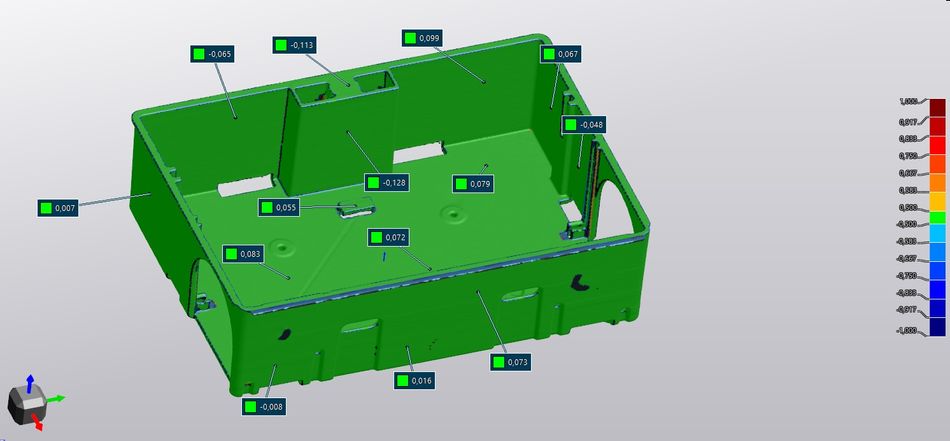

- Dimensional control on the prototype a reporting in VXelements

Portable 3D scanner against measuring arm

Before acquiring HandySCAN 3D, Steelte used a conventional measuring arm, which was very limited in its functions with respect to a portable 3D scanner. Steelte selected the HandySCAN 3D by Creaform for its rapid acquisition speed and scanning precision.

The scanning system – in contrast to the arm – is not limited in capacity and freedom of movement, and can be rotated and moved during scanning, so that all the areas of the object being scanned can be captured rapidly and precisely, even complex geometries, openings and holes.

Moreover, the scanner is easy to transport: packaged in a small transport case, it can be rapidly and easily taken anywhere for digitalizing an object. It does not require rigid configuration like a measuring arm and provides exact measurement results, also in production facilities with difficult environmental conditions.

Alberto Taraschi, from the Steelte technical department: “With its sophisticated technology, ease of use and portability, the innovative scanning system by Creaform allowed us to accelerate scanning processes and produce more precise objects, increasing our productivity. HandySCAN 3D won us over. In light of the positive experience with Creaform – starting from the first demo phase, up to the training courses – we would like to continue collaborating with them and we will surely purchase more Creaform products in the future”.